Teburin Abubuwan Ciki

1. Gabatarwa & Bayyani

Na'urorin lantarki masu sassauƙa suna wakiltar sauyi daga tsarin ƙwaƙƙwaran silicon zuwa na'urori masu sauƙi da dacewa don na'urorin kula da lafiya masu sawa, nunin ninkewa, da na'urori masu auna fata. Matsala mai mahimmanci ita ce kayan aiki mai ɗaukar wutar lantarki don haɗawa. Indium Tin Oxide (ITO), ma'aunin da ake amfani da shi a halin yanzu, yana da rauni kuma yana fama da ƙarancin indium. Wannan takarda ta Baig da Abe ta gabatar da wata madadi mai ban sha'awa: cibiyoyin nanonet na Platinum (Pt) masu haɗin wutar lantarki da aka kera ta hanyar kulawar yanayi da ke haifar da rarraba lokaci a cikin bakin fim na gami na Pt-Ce. Babban ƙirƙira ya ta'allaka ne a cikin samun hanyar sadarwa ta Pt tare da ƙarfin injiniya na musamman (wanda ya tsira sama da zagaye 1000 na lanƙwasa har zuwa radius na 1.5 mm) yayin da yake kiyaye juriya na takarda mai aiki (~2.76 kΩ/sq).

Ma'aunin Aiki Mai Muhimmanci

~2.76 kΩ/sq

Juriya na takarda bayan zagaye 1000 na lanƙwasa

Ƙarfin Injiniya

>1000 zagaye

Zagayen lanƙwasa a radius na 1.5 mm

Kaurin Fim

< 50 nm

Matsakaicin kauri na cibiyar nanonet na Pt

2. Hanyoyi & Tsarin Kera

Dabarar kera tana da sauƙi sosai, tana guje wa rikitaccen lithography. Ya dogara ne akan tsari mai matakai biyu: sanyawa sannan kuma maganin yanayi mai amsawa.

2.1 Shirye-shiryen Tushe & Sanya Gami

Ana sanya bakin fim mai kauri na 50 nm na gami na Platinum-Cerium (Pt-Ce) a kan wani tushe mai sassauƙa na polyimide (PI) ta amfani da sanyawar iska ta zahiri (misali, sputtering). Zaɓin PI yana da mahimmanci saboda tsayin zafinsa da sassauƙarsa.

2.2 Maganin Yanayi & Rarraba Lokaci

Ana sanya fim ɗin da aka sanya a cikin maganin zafi mai girma a cikin yanayi mai ɗauke da Carbon Monoxide (CO) da Oxygen (O₂). Wannan shine mataki mai mahimmanci wanda ke haifar da rarraba lokaci. Maganin yana canza Cerium (Ce) zuwa Cerium Dioxide (CeO₂) mai keɓewa, yayin da Platinum (Pt) ke taruwa kuma ya samar da tsarin cibiyar nanonet mai haɗin kai. Takardar ta gano madaidaicin zafin jiki da ƙofofin lokaci: ƙananan zafin jiki/ƙananan lokaci yana haifar da hanyoyin sadarwa masu haɗin kai, yayin da babban zafin jiki/tsawon lokaci ke haifar da tsibiran nano na Pt da ba su haɗu ba.

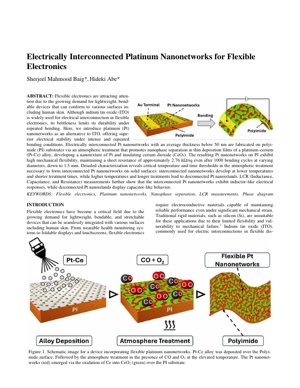

Bayani na Tsari (Hoto na 1): Hoto yana kwatanta na'ura tare da gami na Pt-Ce da aka sanya akan PI. Bayan maganin CO/O₂, wani nau'in nano ya fito inda jajayen tsari kamar gizo (cibiyoyin nanonet na Pt) suke cikin matrix kore (CeO₂) akan tushe.

3. Sakamako & Halayewa

3.1 Binciken Tsari (SEM/TEM)

Hotunan Microscope na Watsawa/Watsawa (SEM/TEM) sun tabbatar da samuwar cibiyar nanonet. Hanyoyin Pt masu haɗin kai sun bambanta da bayanan CeO₂, tare da girman fasalin a kan ma'aunin nanometer, wanda ke ba da gudummawa ga sassauƙar kayan.

3.2 Aikin Wutar Lantarki & Gwaje-gwajen Lanƙwasa

Tsayin wutar lantarki shine sakamako mai ban mamaki. Cibiyoyin nanonet na Pt akan PI suna kiyaye juriya na takarda kusan 2.76 kΩ/sq ko da bayan zagaye 1000 na lanƙwasa a diamita daban-daban, har zuwa radius mai lanƙwasa na 1.5 mm. Wannan yana nuna ƙarfi fiye da ITO, wanda yawanci yana fashe ƙarƙashin ƙarancin damuwa.

3.3 Ma'aunin LCR & Amsar Wutar Lantarki

Ma'aunin Inductance, Capacitance, da Resistance (LCR) sun bayyana alaƙar tsari-da-dukiya mai ban sha'awa:

- Cibiyoyin Nanonet na Pt Masu Haɗin Kai: Suna nuna amsoshin wutar lantarki kamar inductor. Wannan yana nuna ci gaba, hanyar ɗaukar wutar lantarki inda kwararar wutar lantarki ke haifar da filin maganadisu.

- Tsibiran Nano na Pt da ba su Haɗu ba: Suna nuna hali kamar capacitor. Wannan yana nuna tsibiran ɗaukar wutar lantarki da ke keɓance ta tazara masu keɓewa (CeO₂), suna samar da hanyar sadarwar capacitor da aka rarraba.

4. Cikakkun Bayanai na Fasaha & Ƙirar Lissafi

Ana iya sanya aikin a cikin mahallin ka'idar percolation, wanda ke ƙirƙira yadda haɗin kai ke fitowa a cikin hanyoyin sadarwa bazuwar. Juriya na takarda $R_s$ na bakin fim ana bayar da shi ta $R_s = \rho / t$, inda $\rho$ shine juriya kuma $t$ shine kauri. Ingantaccen juriya na cibiyar nanonet yana ƙarƙashin ƙofar percolation da karkatar da hanyoyin Pt. Ƙwayoyin rarraba lokaci suna bin alaƙar irin Arrhenius, inda lokacin magani $t$ da zafin jiki $T$ suka ƙayyade matakin rarraba lokaci: $\text{Yawan Rarraba Lokaci} \propto \exp(-E_a / k_B T)$, inda $E_a$ shine ƙarfin kunnawa kuma $k_B$ shine akai na Boltzmann. Wucewa mahimmin samfurin $T \times t$ yana tura tsarin daga yanayin hanyar sadarwa mai haɗin kai zuwa yanayin tsibiran nano da ba su haɗu ba.

5. Tsarin Bincike & Nazarin Lamari

Tsarin don Kimanta Fasahar Masu Gudanar da Wutar Lantarki Masu Sassauƙa:

- Kayan aiki & Haɓaka Tsari: Kimanta farashi, samuwar kayan aiki (Pt vs. In), da rikitaccen kera (ba tare da lithography ba vs. lithography mai matakai da yawa).

- Ƙarfin Injiniya-Wutar Lantarki: Ƙididdige aiki (juriya na takarda) ƙarƙashin damuwar injiniya mai zagaye (lanƙwasa, shimfiɗa). Ayyana ma'auni na gazawa (misali, ƙaruwar $R_s$ na 20%).

- Yawan Aiki: Kimanta fiye da sauƙin ɗaukar wutar lantarki (misali, amsar LCR, bayyananne, dacewa da rayayyun halittu).

- Shirye-shiryen Haɗin Kai: Dacewa da daidaitattun hanyoyin kera na'urorin lantarki masu sassauƙa/ semiconductor.

6. Bincike Mai Mahimmanci & Fassarar Kwararru

Babban Fahimta: Baig da Abe ba kawai suna gabatar da wani mai gudanar da wutar lantarki mai sassauƙa ba; suna nuna dabarar sarrafa kayan aiki. Ta hanyar amfani da rashin kwanciyar hankali na thermodynamic na gami na Pt-Ce a ƙarƙashin takamaiman yanayi mai amsawa, suna "shirya" hanyar sadarwa mai ɗaukar wutar lantarki mai ƙarfi wanda ke tsara kansa. Wannan ya wuce ƙirar (kamar lithography) zuwa fagen samar da kayan aiki da aka sarrafa, wanda ke tunawa da yadda ƙa'idodin rarraba lokaci ke jagorantar tsari a cikin copolymers block (kamar yadda aka bincika a cikin mujallolin kimiyyar kayan aiki kamar Advanced Materials).

Kwararar Ma'ana: Hujja tana da ƙarfi: 1) ITO yana da aibi (mai rauni, ƙarancin abu). 2) Maganin raga na ƙarfe da ke akwai yana da rikitarwa. 3) Ga madadi mai sauƙi, ba tare da lithography ba. 4) Mahimmin abu shine sarrafa rarraba lokaci ta hanyar T/t. 5) Sakamakon yana da ƙarfi a injiniya kuma yana da ban sha'awa a wutar lantarki (amsar LCR). Haɗin tsakanin sigogin tsari (T, t), tsarin micro (haɗe vs. tsibirai), da dukiyar macro (inductive vs. capacitive) yana da kyau musamman kuma bayanai suna goyan bayansa sosai.

Ƙarfi & Aibobi:

- Babban Ƙarfi: Sauƙin tsari da kyakkyawar alaƙar tsari-tsari-dukiya. Amfani da LCR a matsayin binciken tsarin micro yana da wayo.

- Aibi Mai Mahimmanci: Giwa a cikin ɗaki shine farashi da juriya na takarda. Platinum yana da tsada sau da yawa fiye da ITO ko ma tawada na azurfa. Juriya na takarda na ~2.8 kΩ/sq, yayin da yake tsayayye, yana da yawa ga yawancin aikace-aikacen nuni ko haɗin kai mai yawan mita. Ya dace da na'urori masu auna ko aikace-aikacen ƙarancin wutar lantarki, wanda takardar ta yarda da shi ta hanyar mayar da hankali kan sassauƙa fiye da ɗaukar wutar lantarki.

- Bayanan da ba su da: Bayyananne (mai mahimmanci don nunin) ba a tattauna ba. Tsayin kwanciyar hankali na muhalli (oxidation na fasalin Pt nanoscale?) ba a magance shi ba.

Fahimta Mai Aiki:

- Ga Masu Bincike: Babban ra'ayi—amfani da maganin yanayi don tafiyar da rarraba lokaci a cikin fina-finai na gami—yana da yawa gabaɗaya. Nan da nan bincika wasu tsarin gami (misali, Au-Zr, Ag-Ce) don nemo analogue mai rahusa, mafi ɗaukar wutar lantarki, ko mafi bayyananne. Bincika jurewar shimfiɗawa, ba kawai lanƙwasa ba.

- Ga Manazojin R&D: Wannan fasahar ba mai kashe ITO ba ce don nunin. Matsakaicin kusurwarta na ɗan gajeren lokaci yana cikin na'urori masu auna sassauƙa masu aminci, na musamman inda tsayin aiki ya ba da hujjar farashin Pt (misali, likita, sararin samaniya, ko na'urori masu sawa masu ƙarfi). Ba da fifiko ga aikace-aikacen inda 2.8 kΩ/sq ya yarda.

- Ga Masu Zuba Jari: Kyakkyawan fata mai hankali. Darajar kimiyya tana da girma, amma dacewar kasuwanci ta dogara gaba ɗaya akan nemo tsarin gami wanda ba na Pt ba ko nuna aikace-aikace na musamman, mai daraja inda ƙarfinsa ba za a iya maye gurbinsa ba. Kalli takardu masu biyo baya akan madadin kayan aiki.

7. Aikace-aikacen Gaba & Hanyoyin Ci Gaba

- Dasassun Magunguna na Zamani & Na'urori Masu Sawa na Yau da Kullun: Haɗin dacewar Pt da rayayyun halittu da ƙarfin injiniya na hanyar sadarwa ya dace da haɗin kai na jijiyoyi na dogon lokaci, jagororin bugun zuciya, ko na'urori masu auna glucose da za a iya dasawa waɗanda dole ne su yi lanƙwasa tare da motsin gabobi.

- Da'irori Masu Sassauƙa Masu Ƙarfi: Aikace-aikace a cikin sararin samaniya (eriya masu dacewa akan fikafikan jirgi mara matuki), motoci (na'urori masu auna akan gidajen sassauƙa), ko na'urorin mutum-mutumi na masana'antu inda ake buƙatar lanƙwasa mai tsanani da maimaitawa.

- Fatun Aiki Da Yawa: Yin amfani da amsar LCR, cibiyar nanoret na iya aiki duka a matsayin na'urar auna damuwa da kuma ɓangaren wutar lantarki mara aiki (inductor/capacitor) a cikin Layer ɗaya mai sassauƙa, yana ba da damar sabbin ƙirar da'ira don injinan mutum-mutumi masu laushi.

- Faɗaɗa Tsarin Kayan Aiki: Muhimmin alkiblar gaba shine amfani da wannan ƙa'idar rarraba lokaci na yanayi zuwa wasu tsarin ƙarfe-oxide (misali, na Azurfa, na Tagulla) don rage farashi sosai kuma mai yuwuwar inganta ɗaukar wutar lantarki.

- Haɗin Kai tare da Tushe Masu Shimfiɗawa: Matsawa daga lanƙwasa (PI) zuwa tushe masu shimfiɗawa (misali, PDMS, SEBS) don ba da damar na'urorin lantarki na gaske.

8. Nassoshi

- Baig, S. M., & Abe, H. (Shekara). Electrically Interconnected Platinum Nanonetworks for Flexible Electronics. [Sunan Mujalla, Ƙarar, Shafuka].

- Dong, et al. (Shekara). Laser interference lithography of ITO nanopatterns for flexible electronics. Nano Letters.

- Seo, et al. (Shekara). Gold nanomesh for electrophysiology. Nature Nanotechnology.

- Guo, et al. (Shekara). Au nanomesh via grain boundary lithography. Advanced Functional Materials.

- Adrien, et al. (Shekara). Chemical fabrication of Au nanomesh on PET. Science.

- Bates, F. S., & Fredrickson, G. H. (1999). Block Copolymers—Designer Soft Materials. Physics Today. (Don ƙa'idodin rarraba lokaci).

- Kim, D.-H., et al. (2010). Epidermal Electronics. Science. (Don mahallin na'urori masu sassauƙa, masu haɗin fata).

- Tushen Yanar Gizo: Cibiyar Ƙididdiga da Fasaha ta Ƙasa (NIST) - Kayan Aiki don Na'urorin Lantarki Masu Sassauƙa. (Don ma'auni da ƙalubalen masana'antu).